Nanomaterials May Creatively Reduce Carbon FootprintWhat if we could capture the CO2 from burning fossil fuels and use it to produce other fuels and chemicals that require a carbon supply?

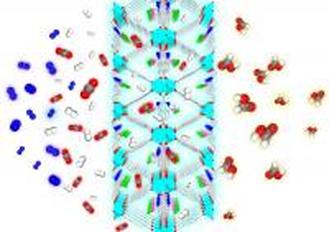

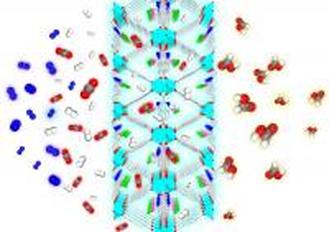

Researchers at the University of Pittsburgh Swanson School of Engineering are using nanomaterials called metal-organic frameworks (MOFs) to take carbon dioxide out of the atmosphere and combine it with hydrogen atoms so that it may be converted it into valuable chemicals and fuels. “Our ultimate goal is to find a low-energy, low-cost MOF capable of separating carbon dioxide from a mixture of gases and prepare it to react with hydrogen,” stated research group leader and principal investigator, Karl Johnson, PhD, in a university press release. “We found a MOF that could bend the CO2 molecules slightly, taking them to a state in which they react with hydrogen more easily.” The Johnson Research Group published their findings in the Royal Society of Chemistry (RSC) journal Catalysis Science & Technology (DOI: 10.1039/c8cy01018h). Their work was illustrated on the cover, which illustrated the process of carbon dioxide and hydrogen molecules entering the MOF and exiting as CH2O2 or formic acid–a chemical precursor to methanol. For this process to occur, the molecules must overcome a demanding energy threshold called the hydrogenation barrier. “The hydrogenation barrier is the energy needed to add two H atoms to CO2, which transforms the molecules into formic acid,” Johnson explained in the release. “In other words, it is the energy needed to get the H atoms and the CO2 molecules together so that they can form the new compound. In our previous work we have been able to activate H2 by splitting two H atoms, but we have not been able to activate CO2 until now,” he continued. The key to reducing the hydrogenation barrier was to identify a MOF capable of pre-activating carbon dioxide. Pre-activation is basically preparing the molecules for the chemical reaction by putting them into the right geometry, the right position, or the right electronic state. The MOF they modeled in their work achieves pre-activation of CO2 by putting it into a slightly bent geometry that may accept the incoming hydrogen atoms with a lower barrier. “There is a barrier to overcome, but in the case of one of the MOFs we proposed, MIL-140-NBF2, the sum of the barriers for bending and subsequent hydrogenation of the activated CO2 is lower than the barrier for direct activation of the CO2 in the MOF from an unbent structure,” said Johnson in an interview with Innov8 Updates. “So, there is a net benefit, a net increase in reaction rate. In a different MOF, MIL-140C-NBF2, we also found a pre-activated bent state for CO2, but the sum of the energies was higher than direct hydrogenation, so in that case, there is no net benefit. This means that the pre-activation involves a delicate balance that must be carefully engineered to have a net benefit.” Another key feature of this new MOF is that it selectively reacts with hydrogen molecules over carbon dioxide, so that the active sites are not blocked by CO2. “We designed a MOF that has limited space around its binding sites so that there is not quite enough room to bind CO2, but there is still plenty of room to bind H2, because it is so much smaller. Our design ensures that the CO2 does not bind to the MOF but instead is free to react with the H molecules already inside the framework,” said Johnson in the press release. Johnson believes perfecting a single material that can both capture and convert CO2 would be economically viable and would reduce the net amount of CO2 in the atmosphere. “You could capture CO2 from flue gas at power plants or directly from the atmosphere,” he said in the release. “This research narrows our search for a very rare material with the ability to turn a hypothetical technology into a real benefit to the world. Works Consulted |

|