1/24/2019

Researchers at UC San Diego studied how feathers latch together and found clues for new adhesives and aerospace materials development.

Nature’s Clues for Better Materials

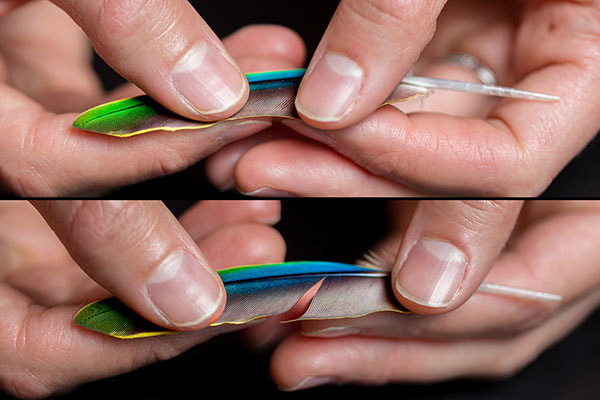

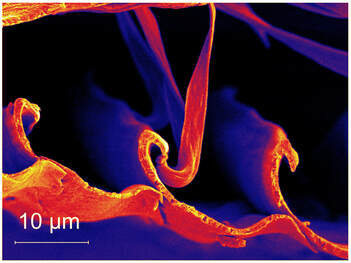

Running a hand back and forth along a feather’s barbs allows you to see how it unzips and zips, pulling itself back together. That zipping action could provide a model for new adhesives and new aerospace materials, according to a news release from University of California San Diego. University engineers have detailed their findings in a January 2019 issue of Science Advances.

Tarah Sullivan, PhD from the Jacobs School of Engineering at UC San Diego, 3D-printed structures that mimic the feathers’ vanes, barbs, and barbules to understand their properties. She wanted to learn how the underside of a feather can capture air for lift, while the top of the feather can block air out when gravity needs to take over.

“As we studied feathers across many species it was amazing to find that despite the enormous differences in size of birds, barbules spacing was constant,” she said in the University news release. Sullivan believes that further studying the vane-barb-barbule structure could lead to the development of new materials for aerospace applications and to new adhesives—think Velcro and its barbs. The paper detailing the findings is titled “Scaling of bird wings and feathers for efficient flight.” Sullivan has built prototypes to prove her point, which she will discuss in a follow-up paper. “We believe that these structures could serve as inspiration for an interlocking one-directional adhesive or a material with directionally tailored permeability,” she said. Bones in Bird WingsSullivan also studied the bones found in bird wings. Like many of her predecessors, she found that the humerus—the long bone in the wing— is bigger than expected. But she went a step further: using mechanics equations, she was able to show why that is. She found that because bird bone strength is limited, it can’t scale up proportionally with the bird’s weight. Instead it needs to grow faster and be bigger to be strong enough to withstand the forces it is subject to in flight. This is known as allometry—the growth of certain parts of body at different rates than the body as a whole. The human brain is allometric: in children, it grows much faster than the rest of the body. By contrast, the human heart grows proportionally to the rest of the body—researchers call this isometry. “Professor Eduard Arzt, our co-author from Saarland University in Germany, is an amateur pilot and became fascinated by the ‘bird wing’ problem. Together, we started doing allometric analyses on them and result is fascinating,” said Meyers in the University news release. “This shows that the synergy of scientists from different backgrounds can produce wonderful new understanding.” |